Call us

07315121945

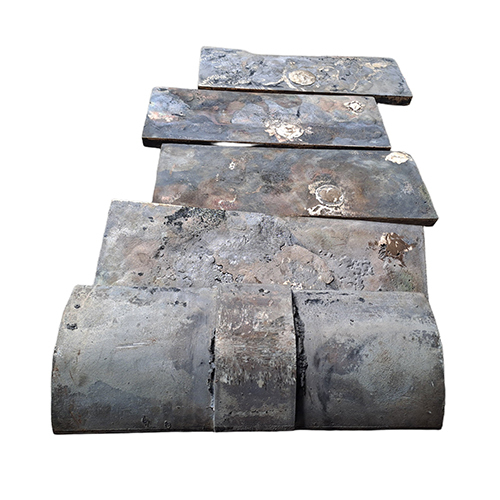

The term "Slipper Pad" can refer to different products depending on the industry. Since you specified "GM Slipper Pad," there is a possibility you are referring to a part used by General Motors (GM), but the general term "Slipper Pad" is most commonly found in:

Industrial Machinery (like Rolling Mills)

Automotive Suspension Systems (like Leaf Springs)

Specialized Engine Designs

Here are general product description content elements for a Slipper Pad in a common industrial context (Rolling Mills) and a brief mention of the automotive application:

These components are typically used in heavy machinery to reduce friction and absorb shock.

Product Name: [Material, e.g., Cast Nylon / Bronze / Polymer] Slipper Pad / Rolling Mill Slipper Bearing

Exceptional Wear Resistance: Engineered from high-grade materials (like Cast Nylon, Gun Metal, or Bronze) to provide a long-lasting solution in high-load and high-speed applications.

Reduced Friction & Self-Lubricating: Low coefficient of friction ensures smooth power transmission and minimizes energy loss, often requiring less external lubrication.

High Impact Strength: Designed to effectively absorb operational shock and vibration, enhancing the durability and reliability of the overall machinery.

Corrosion/Chemical Resistance: Resists degradation from moisture, oils, chemicals, and contaminants often present in industrial environments.

Protects Adjacent Components: Acts as a sacrificial wear part, preventing premature wear on more expensive elements like the spindle, roll, or coupling housing.

Applications: Essential coupling insert used in various heavy industries, most notably Steel Rolling Mills (hot and cold), as well as in guide supports, heavy equipment, and conveyor systems.

Customizable: Available in various sizes (e.g., 200 to 300 MM), materials, and hardness levels (e.g., 70-80 Shore D) to meet specific operational requirements.

Price: